KnowledgeECONOMICS

CONTACT US

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »vertical turbine pump

A connection and fixing device for a suspended semi submersible vertical turbine pump

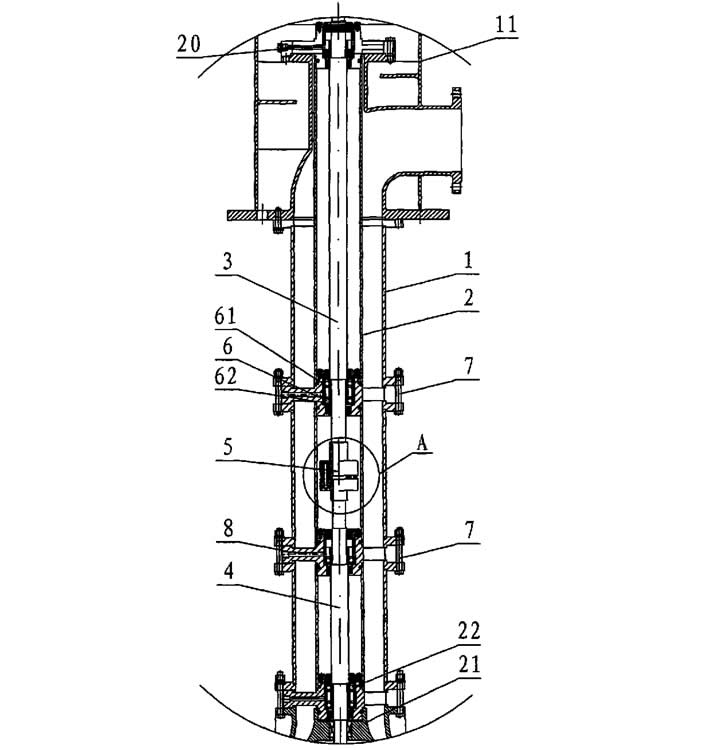

A connection and fixing device for a suspended semi submersible vertical turbine pump, comprising a pump shaft composed of an upper shaft and a lower shaft connected as a whole. The upper end of the pump shaft is installed in a rolling bearing assembly on a bracket, and the lower end of the pump shaft is installed in a bearing of the pump body. A protective pipe and a guide pipe are sequentially fitted from the inside to the outside outside of the pump shaft. The upper and lower shafts are connected by an elastic column pin coupling, and at least one rolling bearing is installed on each of the upper and lower shafts. The protective pipe and the guide pipe are correspondingly connected in sections at the installation of the rolling bearing. This technical method ensures good coaxiality of the pump shaft while reducing the requirements for the machining accuracy and material of the pump shaft. The service life of the relevant rotating parts is beneficial for installation and disassembly.

Technical requirements: A connection and fixing device for a suspended semi submersible vertical turbine pump, comprising a pump shaft composed of an upper shaft (3) and a lower shaft (4) connected as a whole. The upper end of the pump shaft is installed in a rolling bearing assembly (20) on a bracket (11), and the lower end of the pump shaft is installed in a bearing (22) of the pump body (21). A protective tube (2) and a water guide tube (1) are sequentially installed outside the pump shaft from inside to outside. The feature is that an elastic pin coupling (5) is used to connect the upper shaft (3) and the lower shaft (4), and at least one rolling bearing (6) is installed on each of the upper shaft (3) and the lower shaft (4). The protective tube (2) and the water guide tube (1) are correspondingly connected in a segmented manner at the installation location of the rolling bearing (6).